This is a highly automated production equipment which has even got a database management system function in controller. Operator can store production data and recipe into the controller during production. And they can reuse these data and recipe in the future when they need it again.

The patented technology greatly reduced water consumption. Enhancing Technology can make customized design for the whole equipment according to customer’s needs.

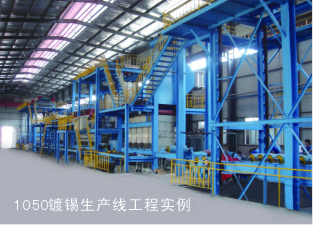

Product thickness: 0.15-0.5 mm, strip width: 350 mm - 1,050 mm, machine speed: 50 - 200 mpm, production capacity: 30,000 - 100,000 tons annually.

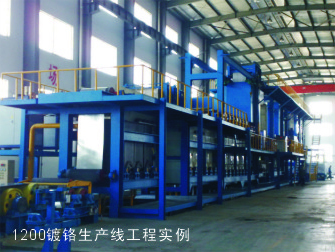

Machine speed, tension and thickness of the chromium plating can be automatically adjusted according to the needs. This highly automated production line does not even need servo alignment device and deviation correction control device.

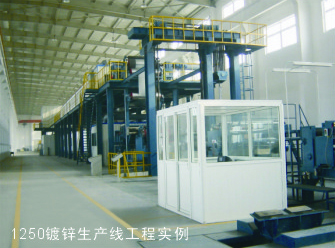

Electrogalvanizing is also called cold galvanizing. It can be widely applied to home appliance, decoration, security door board and hard color coating plate, etc.

Advantage: less investment and low production cost;

Enhancing electrogalvanizing mill can be vertically or horizontally designed according to the needs. Product thickness: 0.15 mm - 20 mm; strip width: 300 mm - 1,250 mm; machine speed: 30 - 120 mpm.