Comparison and Advantage Analysis of Precision 3D Cold Forming Technology

Article Type: Products and Process

Author: Jason Wang (Original)

Abstract: Precision cold rolling technology will gradually replace die drawing and roll drawing technology, and become the main production process and technology of precision cold forming products.

Content:

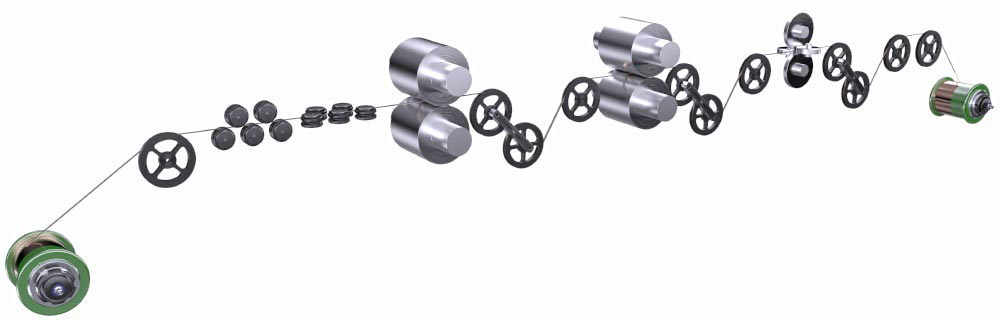

At present, the precision 3D cold forming technology of metal wire can be divided into three processes: die drawing, roll drawing and finish rolling. Die drawing is to use pulling force to pass circular steel wire through a hole die of a specific shape to obtain special-shaped steel wire of corresponding cross-section. Its advantages are less investment in equipment and moderate precision of finished products, but low production efficiency, large die loss and high labor intensity, because of the use of lubricant powder, resulting in poor working environment. Different from die drawing, roll drawing uses two or more unpowered pressure rollers to move along with wire rods, from sliding friction to rolling friction. From effectively improving the service life of roll drawing die, improving the processing accuracy and surface quality of wire rods, the size consistency of wire rods is good, but the technical threshold of roll drawing process is relatively high, production efficiency is low, tooling investment is large, at the same time. Professional cooling device is needed, which is suitable for processing linear wire. With the increasing market demand of multi-varieties, small batch and high precision, high precision finishing rolling equipment emerges as the times require. The wire rod processed by flat rolling, vertical rolling or universal rolling has very high precision and surface quality, which can achieve micron precision, good dimensional consistency, high production efficiency, less manual participation, low labor intensity, environmental protection and no noise. It is especially suitable for coiled wires. However, the high technical threshold of finishing rolling equipment and large one-time investment have seriously hindered the popularization and promotion of the equipment.

The core of precision 3D cold forming technology is the precise matching of equipment and process. From the aspect of equipment, the size of roll determines the rolling force and the size of wire cross section, the speed of roll determines the size of wire rolling linear speed, the surface material of roll is closely related to the raw material of the rolled wire, the surface quality of roll determines the surface quality of finished wire and the radial of roll. Running, axial runout, shaft temperature, deflection and tension control factors determine the processing accuracy and dimensional consistency of finished wire rods. From the aspect of technology, the processing technology of wire rod is arranged according to the mechanical properties, cross-section size, processing accuracy, surface quality and running speed of wire rod raw materials. The reasonable combination of pretreatment, heat treatment, setting-out, straightening, orientation, rolling, roll-drawing, tensioning, lubrication, degreasing, drawing and taking-up processes can effectively improve the processing quality and efficiency. At the same time, it greatly reduces the material defect rate, equipment procurement cost and equipment loss, so as to achieve good economic benefits and equipment benefits.